Then you will need to open the Output Preview window from the drop down menu (ADVANCED / OUTPUT PREVIEW) and for the Simulated Profile select the icc that you want to softproof the PDF to, either ISO Newspaper 26v4.icc for newspaper print or ISO Coated v2 300% ECI.icc for magazine print. Also, at the bottom of the Output Preview window is a.

- Iso Newspaper 26v4.icc Online

- Iso Newspaper 26v4.icc India

- Iso Newspaper 26v4.icc Sri Lanka

- Iso Newspaper 26v4 Icc Download

- Iso Newspaper 26v4.icc Philippines

- Rotary offset newspaper printing according to ISO standard 12647-3 Colour sequence: K-C-M-Y. ISOnewspaper 26v4.icc and WAN-IFRAnewspaper26v5.icc.

- Email or User ID Password. Forgot your password? By logging into ISO ClaimSearch, I agree to comply with the Terms of Use. © 2021 Insurance Services.

COLOURSPACE, GAMUT & INK WEIGHT

RGB

The colourspace where every colour represented is constructed by mixing varying percentages of Red, Green and Blue. It is used in everyday applications such as computer monitors, digital cameras and scanners. It works because it is an illuminated source . . . i.e. it has light shining through it. It is not possible to reproduce colours mixed in RGB onto the printed page (no illuminated source being the fundamental downfall) we have to convert everything to . . .

CMYK

A colourspace where every colour represented is constructed by mixing varying percentages of Cyan, Magenta, Yellow and Key (Black to me and you). The different percentages are achieved by printing different amounts of these colours by using randomly-placed dots on printing plates. Of course, the CMYK printing process has limitations, and that is why a company called Pantone came up with a reference system called . . .

PANTONE

Pantone colours are “Spot” colours and are made up from printing solid areas of ink. Pantone colours are not used in newsprint publications. The make up of the Presses does not cater for anything other than the four process inks (CMYK). However, most pre-Press graphic design programs have Pantone to CMYK colour conversions that match – as close as possible – specified Pantone colours. There is a newsprint alternative, it is . . .

FOCOLTONE

Archant’s own pre-Press and Design Studio departments uses, and recommends the use of, the Focoltone Colour System in all newsprint publications. The complete Focoltone Colour System consists of 763 four-colour combinations of the process colours, in single tints of all four inks from 5% to 85%. The Focoltone system is supported in all commonly-used pre-Press programs . . . InDesign, QuarkXPress, Illustrator, Photoshop.

THE DIFFERENCES BETWEEN ON-SCREEN COLOURS AND THE PRINTED COLOURS

Q Why does the image on my PC look different to the hard copy proof from my ink jet/laser printer which also looks different to the one in the newspaper?

A No device in a publishing system is capable of reproducing the full range of colours viewable to the human eye. Each device operates within a specific colour space that can produce a certain range, or gamut, of colours.

A colour model determines the relationship between values, and the colour space defines the absolute meaning of those values as colours. Some colour models (such as CIE L*a*b) have a fixed colour space because they relate directly to the way humans perceive colour. These models are described as being device-independent. Other colour models (RGB, HSL, HSB, CMYK, and so forth) can have many different colour spaces. Because these models vary with each associated colour space or device, they are described as being device-dependent.

The three colour receptors in the human eye are Red, Green and Blue, PC monitors/TVs display in Red, Green and Blue. Red, Green, Blue (RGB) colours cannot be reproduced accurately when using Cyan, Magenta, Yellow and Black inks from the CMYK printing process. Because of these varying colour spaces, colours can shift in appearance as you transfer documents between different devices. Colour variations can result from differences in image sources; the way software applications define colour; print media (newsprint paper reproduces a smaller gamut than magazine-quality paper); and other natural variations, such as manufacturing differences in monitors or monitor age.

DON'T BE FOOLED BY SCREEN BRIGHTNESS

Our computer monitors, tablets, phones and camera LCDs are all backlit devices. They will always display our images brighter than any physical print. Be sure to correct for this, otherwise your prints may end up much darker than you expect. To get an idea of how your advert will look in print, be sure to soft proof your advert to either ISOnewspaper 26v4 or ISO Coated v2 300% on a correctly calibrated screen to get an idea of how the advert will print. It's always best to calibrate your screen using a colorimeter. Two popular colorimeters on the market are the X-Rite i1 Display PRO and the Datacolor Spyder 4 Elite

How to install ICC profiles on your Windows computer

Right click on the ICC Profile once downloaded and select “Install Profile”.

Any applications (such as Adobe InDesign / Adobe Photoshop etc) that will use the profiles must be restarted to see the new profiles.

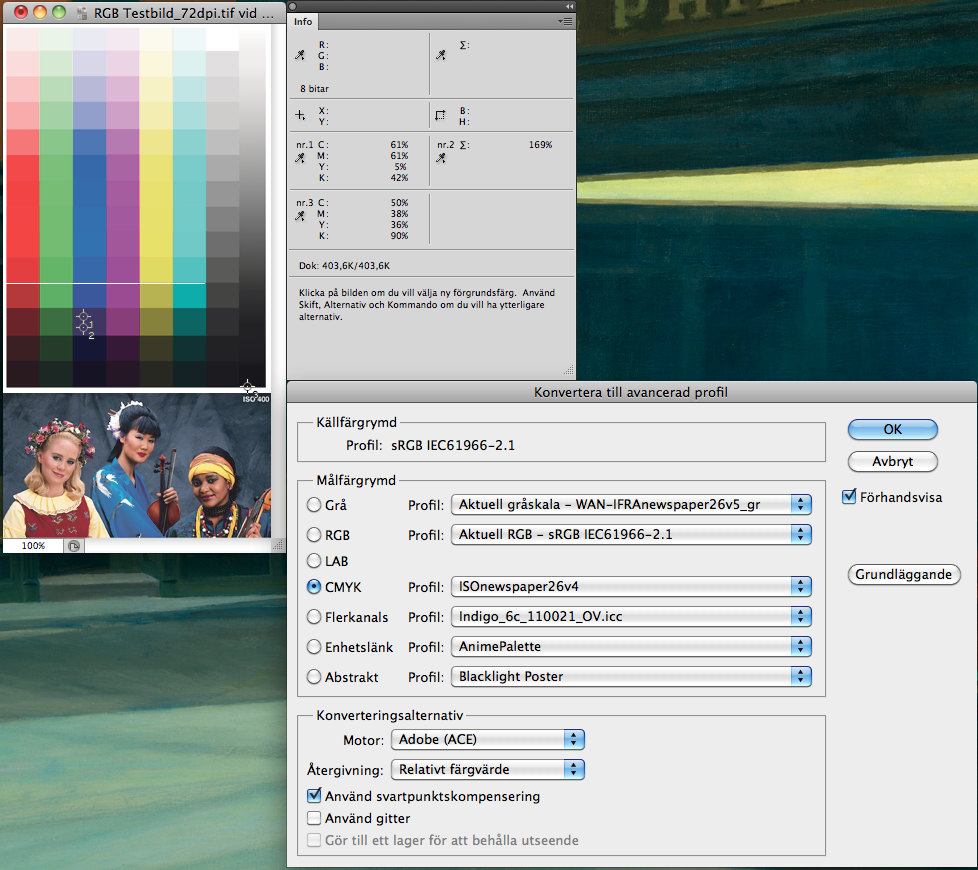

How to install ICC profiles on your computer - Apple / Mac

The ICC profile must be placed in the correct folder for your software to use them. (Macintosh HD > Library > Colorsync > Profiles)

Any applications (such as Adobe InDesign / Adobe Photoshop etc) that will use the profiles must be restarted to see the new profiles.

CONVERSION OF RGB TO CMYK

The easiest way to gain an understanding of the colour conversion process is to view this publication in both hard copy and online versions at the same time. If you are reading this from the newsprint version please go online and, from the front page of Archant Publishing Services website (http://www.digitalnorfolk.com/production), you will find a link to the PageSuite RGB version of this colour guide.

If you are a graphic designer or page designer viewing the PageSuite RGB version and would like a hard copy version of this publication please email Archant Publishing Services Technical Manager Alan Doy at alan.doy@archant.co.uk with contact details.

If you are a prospective contract print customer viewing the PageSuite RGB version and would like a hard copy version of this publication please email Archant Print Sales Manager Ashley Barnes at ashley.barnes@archant.co.uk with contact details.

Wikipedia has some very good information at http://en.wikipedia.org/wiki/RGB_color_model and http://en.wikipedia.org/wiki/CMYK_color_model

RGB = ADDITIVE

The RGB colour model is an additive colour model in which Red, Green and Blue light are added together to reproduce a broad array of colours. The name of the model comes from the initials of the three additive primary colours, Red, Green, and Blue.

Equal values of Red, Green and Blue lightwaves = White.

Overlapping elements (secondary colours) are Cyan, Magenta and Yellow.

CMYK = SUBTRACTIVE

The CMYK model works by partially or entirely masking colours on a lighter, newsprint, background. The ink reduces the light that would otherwise be reflected. Such a model is called subtractive because inks “subtract” brightness from white.

Equal values of Cyan, Magenta and Yellow ink = Black.

Overlapping elements (secondary colours) are Red, Green and Blue.

DESTINATION SPACE

Convert all images to the correct icc profile (ISOnewspaper 26v4 or ISO Coated v2 300% (ECI), this will convert any RGB elements to the correct CMYK colour space and Ink weight. Nb: If ink weight is in excess of 240% for newsprint and 300% for magazines, detail in any shadow areas will be lost as the paper becomes over saturated.

GAMUT

In colour reproduction either on computer monitors, desktop printers, newsprint presses or in photography, the gamut is a subset of colours. The most common usage refers to the subset of colours which can be accurately represented in a given circumstance, such as within a given colour space (i.e. RGB on a monitor or CMYK on a Press). Another sense, less frequently used but no less correct, refers to the complete set of colours found within an image at a given time. In this context, digitising a photograph, converting a digitised image to a different colour space, or outputting it to a given medium using a certain output device generally alters its gamut, in the sense that some of the colours in the original are lost in the process.

The representation of gamuts are sRGB to the left and CMYK for newsprint to the right. In general terms . . . when using a digital camera or desktop scanner any images taken or scanned will, by default, be written away in sRGB colour mode (far left). When converted into CMYK images for use on newsprint the range of colours available is the smaller gamut (considerably smaller gamut) to the right.

Designers have the ability to check their colour gamut in any of the professional image editing programs (Photoshop CS3 screen shots below). The image (below left) shows the selection of the red in the main window to be at top right. The “Warning Triangle” tells the designer the colour cannot be made in CMYK. The image (below right) shows where the selection moves to – and the closest CMYK colour available – when the “Warning Triangle” is clicked.

Designers also have the ability to check their colour gamut in any image (Photoshop CS3 screen shot below). In reality most leave the conversion to the software. The “Information” palette shown on top of the image of the tractor shows exclamation marks in the right hand CMYK info. This is where it’s out of gamut and cannot be converted exactly.

INK WEIGHT (TAC)

This is the area where most, if not all, colour issues stem from in newspaper printing. If a designer is manually colour correcting images for newsprint in Photoshop none of the default CMYK colour spaces use ISOnewsprint26v4.icc 240% Total Area Coverage (TAC) colour space.

The US Web (Coated) profile in early versions of Photoshop is, as it says in the name, for magazine work in the USA – a 300% TAC. FOGRA 39 in Photoshop CS6 in both General Purpose and Pre-Press CMYK settings is a 350% TAC magazine profile.

Iso Newspaper 26v4.icc Online

Download ISOnewsprint26v4.icc profile for newsprint

Download ISO Coated v2 300% (ECI).icc profile for magazine print

It is simply a matter of loading the .icc profile into Photoshop, etc. via Edit – Colour Settings – Working Spaces and letting the software handle the sRGB to CMYK conversion. The alternative is to follow a similar route to Archant Publishing Services in-house colour correction . . . use one of the many Automatic Image Processing solutions.

The above Contone Image is the CMYK result of processing the original sRGB off a Nikon Coolpix L810 Digital Still Camera (DSC) via Photoshop using the default colour settings of the program. Result is too much ink coverage within the image – 300% ink coverage instead of 240%. Below is same image with FOGRA 39 and 350% ink coverage.

The image to the left shows (in red) where there is too much ink.

Example of over ink weight images printing on Newspaper stock

Figure 1. This supplied image looks ok on screen and has been supplied in the CMYK colour space. The image has been colour corrected to the wrong icc print profile (U.S. Web Coated (SWOP) v2) and has an ink weight in excess of 340% because of this. For reproduction on absorbent newspaper the ink weight is miles too high and the graphics designer should have used the icc profile ISOnewspaper 26v4 when correcting the image in Photoshop as this would have lowered the ink weight (TAC) to 240%.

Figure 2. This is how figure 1 has printed. The over ink weight image has resulted in the dark areas of the image having excessive ink laid down on the press run and has caused the dark areas to lose detail and fill/bleed in, resulting in an image that is too dark with no detail in the shadows compared to the screen version (figure 1)

Figure 3. Has been supplied in the correct colour space (CMYK) and has been colour corrected to the correct icc profile (ISOnewspaper26v4) which has reduce the ink weight to 240%. Figure 3 will print as intended and is much brighter in the darker areas with visible detail in the shadows.

Nb: For printing on newspaper, use the ISOnewspaper 26v4 icc profile which has a TAC (Total Area Coverage / Ink Weight) of 240%. For printing on glossy magazine stock use ISO Coated v2 300% ECI icc profile which has a TAC (Total Area Coverage / Ink Weight) of 300%.

FONTS & TYPE

QUALITY OF IMAGES

RECOMMENDED COLOUR

TABLOID SIZES

MAGLOID & QUARTERFOLD SIZES

Newspaper printingprocessstandard ISO 12647-3:2004

The new newspaperprinting processstandard comes into effect on 1st July 2004! Basis: DIS/ISO12647-3:2004Ref.: Newspaper offset (coldset) and proof printing on standardnewsprint

The revised version ofISO 12647-3:2004,the standard for the newspaper offset printing process, is largelycomplete.The most important change is that the existing varying dot gain valuesfor different processes have been replaced by a single,process-independentdot gain. Agencies and ad suppliers can now supply all newspapersworldwide(with the exception of the USA) with a single CMYK data set, separatedin accordance with ISOnewspaper26v4.

Atc-5030 manual. The existing profiles:

ISO 9001:2015 Quality management systems - Requirements, is the 5th edition of this standard. ISO 9001:2015 specifies requirements for a quality management system when an organization: a) needs to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory. Ads with correct colour profile for a quality colour reproduction! Medibel+ joins the international ISO12647-3 standard'ISOnewspaper26v4' for newspapers as to.

QUIZ (for Germany),

CINCO (for Spain),

CQ2 (for Italy),

KWIK (for theNetherlands)

ICONS (for India) and

ACER (for Latin America)

are no longer valid as ofimmediately.

The introduction of theprocess-independentdot gain and corresponding standard newspaper profile on 1st July 2004will make newspaper houses more customer-friendly. However, the directfurther processing/printing of CMYK data separated in accordance withISOnewspaper26v4presupposes the conversion/adaptation of the in-house processes at thenewspaper operations on the basis of DIS/ISO 12647-3:2004, or theadjustmentof the data reception and following aligning of all internal processes.The objective of the standardisation is to obtain consistent colourprintingat a high quality level in all newspapers.

The ZMG and IFRAnewspaper printingquality initiative (QUIZ), a project supported by the Federal Germanprintingand media association (bvdm), published a standard profile and twospecialprofiles for international newspaper printing for the first time inMarch2001. Since then, the concept of connecting printing standardisationbasedon ISO 12647-3 and colour management has proven successful. Manynewspaperhouses and ad suppliers support it and have used the published ICCcolourprofiles for newspaper printing for many years.

IFRA has been able tobuild onthe experience gained from numerous national and internationalstandardisationprojects and incorporate its findings into the new ISOnewspaper-processstandard. Thus the original QUIZ profiles from the year 2001 werecontinuallyreplaced by new and better adapted profiles.

The name of the new IFRAstandardprofiles for newspaper printing, valid with effect from 1st July 2004,is:

It is usually around 300 mb in size. Click and download to your disk latest patch level of SWPM (SWPM10SP05 0-200009707.SAR in my case). Files which begins with 70 (70SWPM10SP05 0-200009707.sar here) can install only SAP NW 7.0. Sapcar command. File without 70 at the beginning installs all version above 7.0 – so 7.1, 7.3. Scroll down where you can see software packages.

ISOnewspaper26v4.icc,colourprofile

ISOnewspaper26v4_gr.icc,greyscale profile

These profiles have beentestedsuccessfully in practice by various newspaper operations. The newstandardprofile is available for downloading from this web site with immediateeffect.

The profiles correspondin principleto the existing standard profiles and the visual results they achieve.All those who to date have used the standard profileNewspaper_QUIZ_22_02.03V2.icmor Newspaper_QUIZ_28_02.03V2.icm should use this profile in the future.It differs from the existing profile by the following details:

* Compensation of a dotgainof 26 %.

* Orientation towardsadaptedprimary and secondary colours of the new DIS/ISO 12647-3:2004.

* characterising datawere recordedon a white measuring background.

* Maximum GCR

The maximum total inkingof theprofile ISOnewspaper26v4.icc is 240 %. The maximum depth in an image isreproduced with

Cyan 59 %,

Iso Newspaper 26v4.icc India

Magenta 45 %,

Yellow 41 % and

Black 95 %.

Iso Newspaper 26v4.icc Sri Lanka

The file name V4 standsfor:Version 4 of the standard newspaper profile.

From this colour profile,a greyprofile was additionally produced that is made available under the nameISOnewspaper26v4_gr.icc. For example, the grey profile can be used forthe automatic conversion of colour images into grey scale images inimageprocessing programs, preflight systems or colour servers.

Profile production

The production of theprofileis based on the measured colour data from different newspaper printingplants worldwide. For this purpose, in each case prints made with theCMYKtestform ISO 12642 with 928 colour patches, also known as IT8.7/3, weremeasured. Measurement was done in accordance with ISO 12647-1, 5.6,i.e.:2° viewer, D50 light, geometry 45°/0°or 0°/45°, ona white and black measuring background. The averaged measured data, onwhich the profile production is based, are available with immediateeffecton the ICC web site: www.color.org.

ISOnewspaper26v4.icc wascompiledtaking into account the specifications and recommendations of ISO12647-3:2004.A maximum GCR was used for separating in order minimise colourfluctuationsin print (see Ifra Special Report 2.16). At the same time care wastakento ensure that no greying occurs in sensitive skin tones. Detailedseparationparameters are included in Readme attached to the profiles.

ISOnewspaper26v4.icc isbasedexclusively on colour measurements on a white measuring background. Ablackmeasuring background is, in accordance with ISO/DIS 12647-3:2004, onlypermissible for process control in print. Targets and tolerances forcheckingprint against black and all additional process parameters are listed in'DIS_ISO 12647-3_2004_e.pdf' (Important: reference values forwhite backing have been slightly changed). The properties of the whitemeasuring background are standardised. See www.fogra.org forinformationon which papers and materials are suitable as a basis for carrying outstandardised measurement on devices with black measuring table.

Proof printing withISOnewspaper26v4.icc

We recommend theUGRA/FOGRA mediawedge CMYK 2.0 as a suitable means of quality control. This can be usedto check a proof, on the basis of target values, for the correctreproductionof the applied process. The media wedge must be measured on a whitebackgroundin order to obtain the correct reference values. From FOGRA, you canobtaina package consisting of UGRA/FOGRA media wedge CMYK as well as an Exceltable with latest target values for colour-binding proof output.

If possible, formeasuring datafor the production of profiles for proofing instruments, a whitebackgroundshould also be used in order to ensure compatibility with printprofilesand colour matching conditions.

Downloading the profiles

Downloading of thestandard profileis free of charge and without restriction. No technical guarantee forthesmooth functioning of the profiles in the different IT environments canbe given. Download at IFRA-Website.

Iso Newspaper 26v4 Icc Download

.

Iso Newspaper 26v4.icc Philippines

.© 2020Copyright by rainer wagner